How to Reduce Excess and Obsolete Inventory

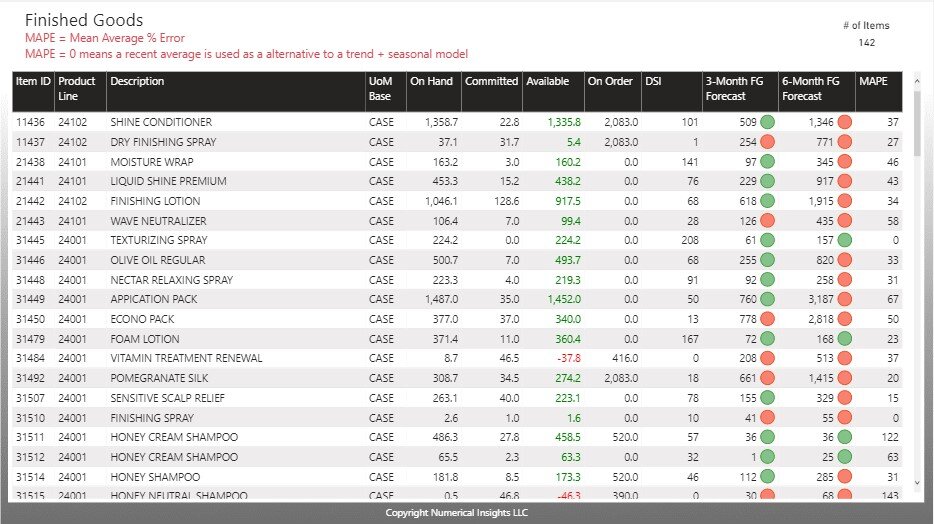

Check out our inventory management dashboard for small and medium-sized businesses.

You’ve been summoned to a meeting with your CEO and CFO. They are furious. The CFO has discovered that you have over $1,000,000 tied up in inventory and it’s been that way for the last six months. They want to know what’s going on.

“We need you to free up cash flow from our inventory so we can use it to fund new product development. What’s the problem? Why do we have so much inventory?”

How You Got There

“We’re sitting on a large inventory of parts that were purchased to make products we don’t sell anymore. Our suppliers don’t offer returns so we’re trying to find a distributor that might want to sell these parts for us. If no-one wants them, we’re stuck and will have to write them off as a loss.”

Your CEO and CFO don’t want to hear this.

"Writing it off as a loss will not fund our product development project. Are you telling me all of this inventory is obsolete?”

You continue your explanation.

“Not exactly. We also have excess inventory from overseas suppliers. We purchased high levels of inventory to cover long lead times of overseas shipments and to leverage quantity discounts. We wanted to provide customers with high service levels by always having parts in-stock… but then market forces drove the monthly demand of some products down substantially. We’re now sitting on, in some cases, more than a year’s worth of inventory.”

The Double Impact of Excess and Obsolete Inventory

You worked hard, you wrote great contracts and you negotiated excellent payment terms. You realize at that moment that there is a double punishment associated with obsolete and excess inventory.

Punishment #1: You can’t access the cash tied up in inventory.

Punishment #2: You’re going to spend a lot of time, resources and money trying to determine the best way to get rid of it.

High Rates of Excess and Obsolete Inventory for Manufacturers

Excess and obsolete inventory for manufacturers can be 15-20% of stock. Warehouses often expect 15% of products to be returned, rejected or become obsolete. The total cost of this inventory can be as high as 25% when considering the cost of the storage, shrinkage, damage and the time value of money.

The impact of excess and obsolete inventory is felt the greatest when thinking about the amount of cash that is tied up in product that can’t be sold to customers. In many cases, this inventory sits tucked away in a dusty corner of the factory or warehouse for extended periods of time. It rarely becomes supply chain’s top priority to relieve the company of this burden.

5 Ways to Dispose of Inventory

First and foremost, ensure your inventory is safe for disposal. If it can pose a liability in any way, seek expert advice before proceeding.

Find a customer or distributor who may want it. Sometimes when products become obsolete, there are companies that wish to run their old equipment for as many years as possible. If you’re carrying obsolete parts for their old equipment, they may be a possible buyer for those parts.

Modify the parts to make them usable for something else. Sometimes a fitting or internal component change can make the parts useful for another product or a new product. For this option, weigh the cost of the modifications against the value of the obsolete parts. If it’s going to cost $25,000 to modify $5,000 worth of obsolete inventory to be able to sell it for $10,000, then…

Auction off the parts. If you need to dispose of the inventory quickly or the cost of modifications doesn’t make sense, you may be able to hire an auction service. Again, weigh the cost of this action against the value of the obsolete parts.

If your inventory is a multi-part unit, can the unit be taken apart to salvage any useful parts from it? Does the value of the salvaged parts make it worth the cost of the labour to conduct this action?

Donate to a charity to obtain a tax credit. This option is more applicable to people with finished goods inventory. It is far less likely to be an option for a manufacturer carrying parts inventory. Check out EAL Green as one example that has been used by manufacturers. They use the money they generate to create student scholarships.

I’ve listed 5 ways above. If you’ve exhausted the options above and you’re reading #6, it means you may need to walk into your accountant’s office and ask, “How do we write off scrap?”

How to Minimize Excess and Obsolete Inventory

As you head back to your office you begin to think about how you to avoid this situation in the future.

First, you will pay more attention to product demand data. Neither you nor your team was looking at the demand numbers and the decreasing patterns. Every product has a life cycle and you keep ending up with excess inventory every time you come to the end of production for a product. If no-one on your team is mathematical, it may be worth it to obtain analytical expertise outside of your company.

How to Use Data for Inventory Decisions

Using both sales and inventory data, you learn that you can display a list of all of the items you sell and the rate at which each one sells. Some items may sell at a rate of 10 per day and others may sell 2 in the next six months. The next time a supplier calls you and offers “an excellent deal on a bulk purchase,” you will be able to look at your inventory usage rates and know exactly how many days of inventory that “excellent deal” represents. Sometimes, the number of days of inventory is too high a price to pay when you consider that you’re that requires licking up cash in inventory for a long time.

As an informed purchasing professional, you commit to researching forecasting methods and inventory level calculations or at least locating the expertise to do so.

Finally, you realize that no-one was really keeping an eye on the accuracy of your inventory. You only cycle count once per year before year end, so the numbers are accurate for the balance sheet. Throughout the year, you’re just not quite sure how accurate the inventory levels are inside your inventory management system or home-grown database records. You commit to reading up on the ABC method of inventory.

With your new found commitment to supply chain analytics, you commit to creating an inventory and product demand dashboard to keep these important numbers in front of you at all times. You are now armed for better decision-making.

Real-world Case Study

Thirty years ago, ABC company was a small, family-operated business. Year after year, they operated the business much the same way they had always done. Three years ago, they realized that something had to change. The business was no longer profitable.

They had stored their business data but did not possess the skills to conduct a deep analysis into their inventory and product profitability. Using this data, Tracey Smith from Numerical Insights LLC provided the owners with information on which inventory was “dead,” the rates at which every item sold, and the number of days of inventory in stock for all items.

Additionally, a sales volume-profit analysis identified opportunities for this company to reduce the number of size variations they were offering. Low-volume, low-margin products could be phased out by transitioning customers to higher-margin options.